Products

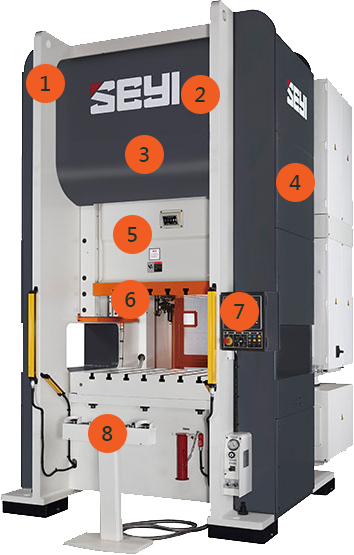

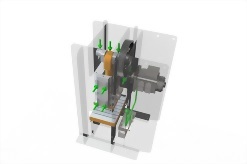

SD Series|Solid Frame Crank Servo Press

Features a extreme acceleration/ deceleration

Extremely precise dimensions

High efficiency

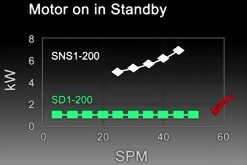

(Other brand)

Due to insufficient torque at low revolution, high revolution has to be used with deceleration as well.

|

Model |

SD1-80 |

SD1-160 |

SD1-200 |

SD1-300 |

||

|

Capacity |

kN |

800 |

1600 |

2000 |

3000 |

|

|

Stroke Length |

mm |

180 |

220 |

250 |

300 |

|

|

Strokes per Minute |

SPM |

~ 80 |

~ 60 |

~ 50 |

~ 40 |

|

|

Tonnage Rating Point |

mm |

5 |

6 |

6 |

6 |

|

|

Die Height |

mm |

330 |

400 |

450 |

550 |

|

|

Slide Adjustment |

mm |

80 |

100 |

110 |

120 |

|

|

Slide Area(LRxFB) |

mm |

700x460 |

900x580 |

1000x670 |

1150x800 |

|

|

Bolster Area(LRxFB) |

mm |

950x680 |

1150x760 |

1300x870 |

1450x1050 |

|

|

Bolster Thickness |

mm |

140 |

165 |

180 |

200 |

|

|

Bolster Height(w/ Mounts) |

mm |

989 |

1054 |

1134 |

1154 |

|

|

Window Opening(FBxUD) |

mm |

680x280 |

760x350 |

870x400 |

1050x450 |

|

|

Floor Space Required |

mm |

1961x2050 |

2161x2557 |

2224x2761 |

2414x3157 |

|

|

Press Height(w/ Mounts) |

mm |

3050 |

3610 |

3985 |

4460 |

|

|

Max. Upper Die Weight |

kg |

300 |

500 |

800 |

1300 |

|

|

Required Air Pressure |

MPa |

0.5 |

0.5 |

0.5 |

0.5 |

|

|

Die Cushion |

Capacity |

kN |

60 |

80 |

100 |

140 |

|

Stroke Length |

mm |

95 |

110 |

130 |

140 |

|

|

Cushion Pad Area(LRxFB) |

mm |

480x340 |

560x370 |

700x450 |

700x450 |

|

|

Model |

SD2-160 |

SD2-200 |

SD2-300 |

SD2-400 |

SD2-500 |

||

|

Capacity |

kN |

1600 |

2000 |

3000 |

4000 |

5000 |

|

|

Stroke Length |

mm |

220 |

250 |

300 |

350 |

350 |

|

|

Strokes per Minute |

SPM |

~ 60 |

~ 50 |

~ 40 |

~ 40 |

~ 40 |

|

|

Tonnage Rating Point |

mm |

6 |

6 |

6 |

6 |

6 |

|

|

Die Height |

mm |

450 |

500 |

600 |

650 |

650 |

|

|

Slide Adjustment |

mm |

100 |

110 |

120 |

130 |

130 |

|

|

Slide Area(LRxFB) |

mm |

1620x580 |

1900x670 |

2280x800 |

2380x1000 |

2380x1100 |

|

|

Bolster Area(LRxFB) |

mm |

1910x760 |

2200x870 |

2580x1050 |

2680x1200 |

2680x1300 |

|

|

Bolster Thickness |

mm |

160 |

170 |

200 |

200 |

200 |

|

|

Bolster Height(w/ Mounts) |

mm |

1064 |

1114 |

1264 |

1428 |

1428 |

|

|

Window Opening(FBxUD) |

mm |

760x400 |

870x450 |

1050x500 |

1200x550 |

1300x550 |

|

|

Floor Space Required |

mm |

2921x2510 |

3099x2666 |

3519x3115 |

3733x3250 |

4000x3400 |

|

|

Press Height(w/ Mounts) |

mm |

3687 |

4099 |

4710 |

5117 |

5204 |

|

|

Max. Upper Die Weight |

kg |

800 |

1300 |

1800 |

2500 |

2700 |

|

|

Required Air Pressure |

MPa |

0.5 |

0.5 |

0.5 |

0.5 |

0.5 |

|

|

Die Cushion |

Capacity |

kN |

80x2 |

100x2 |

140x2 |

140x2 |

140x2 |

|

Stroke Length |

mm |

110 |

130 |

140 |

140 |

140 |

|

|

Cushion Pad Area(LRxFB) |

mm |

560x370x2 |

700x450x2 |

700x450x2 |

700x450x2 |

700x450x2 |

|

※ This specification is subject to change without notice.

|

Model |

SD1-88 |

SD1-176 |

SD1-220 |

SD1-330 |

||

|

Capacity |

U.S.ton |

88 |

176 |

220 |

330 |

|

|

Stroke Length |

in |

7.09 |

8.66 |

9.84 |

11.81 |

|

|

Strokes per Minute |

SPM |

~ 80 |

~ 60 |

~ 50 |

~ 40 |

|

|

Tonnage Rating Point |

in |

0.20 |

0.24 |

0.24 |

0.24 |

|

|

Die Height |

in |

12.99 |

15.75 |

17.72 |

21.65 |

|

|

Slide Adjustment |

in |

3.15 |

3.94 |

4.33 |

4.72 |

|

|

Slide Area(LRxFB) |

in |

27.56x18.11 |

35.43x22.83 |

39.37x26.38 |

45.28x31.50 |

|

|

Bolster Area(LRxFB) |

in |

37.40x26.77 |

45.28x29.92 |

51.18x34.25 |

57.09x41.34 |

|

|

Bolster Thickness |

in |

5.51 |

6.50 |

7.09 |

7.87 |

|

|

Bolster Height(w/ Mounts) |

in |

38.94 |

41.50 |

44.65 |

45.43 |

|

|

Window Opening(FBxUD) |

in |

26.77x11.02 |

29.92x13.78 |

34.25x15.75 |

41.34x17.72 |

|

|

Floor Space Required |

in |

77.20x80.71 |

85.08x100.67 |

87.56x108.70 |

95.04x124.29 |

|

|

Press Height(w/ Mounts) |

in |

120.08 |

142.13 |

156.89 |

175.59 |

|

|

Max. Upper Die Weight |

LBS |

661 |

1102 |

1763 |

2866 |

|

|

Required Air Pressure |

PSI |

71 |

71 |

71 |

71 |

|

|

Die Cushion |

Capacity |

U.S.ton |

6.6 |

8.8 |

11 |

15.4 |

|

Stroke Length |

in |

3.74 |

4.33 |

5.12 |

5.51 |

|

|

Cushion Pad Area(LRxFB) |

in |

18.90x13.39 |

22.05x14.57 |

27.56x17.72 |

27.56x17.72 |

|

|

Model |

SD2-176 |

SD2-220 |

SD2-330 |

SD2-440 |

SD2-550 |

||

|

Capacity |

U.S.ton |

176 |

220 |

330 |

440 |

550 |

|

|

Stroke Length |

in |

8.66 |

9.84 |

11.81 |

13.78 |

13.78 |

|

|

Strokes per Minute |

SPM |

~ 60 |

~ 50 |

~ 40 |

~ 40 |

~ 40 |

|

|

Tonnage Rating Point |

in |

0.24 |

0.24 |

0.24 |

0.24 |

0.24 |

|

|

Die Height |

in |

17.72 |

19.69 |

23.62 |

25.59 |

25.59 |

|

|

Slide Adjustment |

in |

3.94 |

4.33 |

4.72 |

5.12 |

5.12 |

|

|

Slide Area(LRxFB) |

in |

63.78x22.83 |

74.80x26.38 |

89.76x31.50 |

93.70x39.37 |

93.70x43.31 |

|

|

Bolster Area(LRxFB) |

in |

75.20x29.92 |

86.61x34.25 |

101.57x41.34 |

105.51x47.24 |

105.51x51.18 |

|

|

Bolster Thickness |

in |

6.30 |

6.69 |

7.87 |

7.87 |

7.87 |

|

|

Bolster Height(w/ Mounts) |

in |

41.89 |

43.86 |

49.76 |

56.22 |

56.22 |

|

|

Window Opening(FBxUD) |

in |

29.92x15.75 |

34.25x17.72 |

41.34x19.69 |

47.24x21.65 |

51.18x21.65 |

|

|

Floor Space Required |

in |

115.00x98.82 |

122.01x104.96 |

138.54x122.64 |

146.97x127.95 |

157.48x133.86 |

|

|

Press Height(w/ Mounts) |

in |

145.16 |

161.38 |

185.43 |

201.46 |

204.88 |

|

|

Max. Upper Die Weight |

LBS |

1764 |

2866 |

3968 |

5512 |

5952 |

|

|

Required Air Pressure |

PSI |

71 |

71 |

71 |

71 |

71 |

|

|

Die Cushion |

Capacity |

U.S.ton |

8.8x2 |

11x2 |

15.4x2 |

15.4x2 |

15.4x2 |

|

Stroke Length |

in |

3.74 |

4.33 |

5.12 |

5.51 |

5.51 |

|

|

Cushion Pad Area(LRxFB) |

in |

18.90x13.39x2 |

22.05x14.57x2 |

27.56x17.72x2 |

27.56x17.72x2 |

27.56x17.72x2 |

|

※ This specification is subject to change without notice.

Auto parts in Mexico

- The combination of pendulum mode with optimized processing speed increases precision of product forming and the productivity at the same time.

- Oil coolant for automotive engine

Auto parts in Japan

- With application of optimized processing speed and curve, the lifetime of die increases and the original 7 strokes of product processing needed reduces to 1 stroke.

- Automotive ABS seals