Products

SDG Series|Straight Side Crank Servo Press

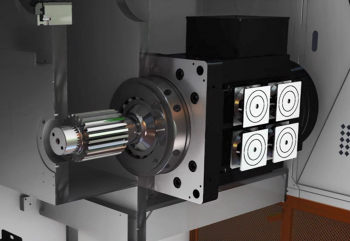

- Powerful direct drive transmission with flexible and easy-to-use operating system.

- Suitable for high tensile strength steel product.

- Tie-rod structure for minimal deflection, accurate parts and machine durability.

- Design makes it easy to integrate automation.

- Saving energy and environmental friendly.

- Crank type design. Up to 2 times of productivity for progressive tooling with swinging (pendulum) motion.

|

Model |

SDG2-400 |

SDG2-600 |

SDG2-800 |

SDG2-1000 |

SDG2-1200 |

|||

|

Capacity |

kN |

4000 |

6000 |

8000 |

10000 |

12000 |

||

|

Stroke Length |

mm |

350 |

350 |

350 |

400 |

400 |

||

|

Pendulum Motion Stroke Length |

mm |

100 |

100 |

100 |

140 |

140 |

||

|

Strokes per Minute |

SPM |

~50 |

~50 |

~50 |

~50 |

~50 |

||

|

Pendulum Motion Strokes per Minute |

SPM |

~ 74 |

~ 74 |

~ 74 |

~ 72 |

~ 72 |

||

|

Tonnage Rating Point |

mm |

6.5 |

6.5 |

6.5 |

6.5 |

6.5 |

||

|

Die Height |

mm |

700 |

700 |

800 |

800 |

800 |

||

|

Slide Adjustment |

mm |

250 |

250 |

300 |

300 |

300 |

||

|

Slide Area |

1 |

mm |

2500×1400 |

2500×1550 |

2800×1550 |

3100×1550 |

3400×1550 |

|

|

2 |

2800×1400 |

2800×1550 |

3100×1550 |

3400×1550 |

3700×1550 |

|||

|

3 |

3100×1400 |

3100×1550 |

3400×1550 |

3700×1550 |

4000×1550 |

|||

|

4 |

3400×1400 |

3400×1550 |

3700×1550 |

4000×1550 |

4300×1550 |

|||

|

Bolster

Area |

1 |

mm |

2500×1400 |

2500×1550 |

2800×1550 |

3100×1550 |

3400×1550 |

|

|

2 |

2800×1400 |

2800×1550 |

3100×1550 |

3400×1550 |

3700×1550 |

|||

|

3 |

3100×1400 |

3100×1550 |

3400×1550 |

3700×1550 |

4000×1550 |

|||

|

4 |

3400×1400 |

3400×1550 |

3700×1550 |

4000×1550 |

4300×1550 |

|||

|

Bolster Thickness |

mm |

180 |

250 |

250 |

250 |

300 |

||

|

Window Opening |

Bolster Only |

(FB × UD) |

mm |

1100×600 |

1300×600 |

1500×700 |

1500×700 |

1500×700 |

|

Front to Back Rolling Bolster |

1100×600 |

1300×600 |

1500×700 |

1500×700 |

1500×700 |

|||

|

Left to Right Rolling Bolster |

1700×800 |

1850×800 |

1850×900 |

1850×900 |

1850×900 |

|||

|

Max. Upper Die Weight |

Ton |

4 |

5 |

5.5 |

6 |

7 |

||

|

Required Air Pressure |

MPa |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

||

|

Bolster Height |

Fixed Bolster |

mm |

850 |

850 |

850 |

850 |

850 |

|

|

Rolling Bolster |

660 |

660 |

660 |

740 |

740 |

|||

|

Die Cushion |

Type |

Cylinder |

Cylinder |

Cylinder* |

Cylinder* |

Cylinder* |

||

|

Capacity |

kN |

600 |

1000 |

1200** |

1500 |

1500 |

||

|

Stroke Length |

mm |

200 |

200 |

220 |

220 |

220 |

||

|

Adjustment |

mm |

200 |

200 |

220 |

220 |

220 |

||

|

Cushion Pad Area |

1 |

mm |

2000×900 |

2000×950 |

2300×1300 |

2600×1300 |

2900×1300 |

|

|

2 |

2300×900 |

2300×950 |

2600×1300 |

2900×1300 |

3200×1300 |

|||

|

3 |

2600×900 |

2600×950 |

2900×1300 |

3200×1300 |

3500×1300 |

|||

|

4 |

2900×900 |

2900×950 |

3200×1300 |

3500×1300 |

3800×1300 |

|||

|

Model |

SDG4-400 |

SDG4-500 |

SDG4-600 |

SDG4-800 |

SDG4-1000 |

|||

|

Capacity |

kN |

4000 |

5000 |

6000 |

8000 |

10000 |

||

|

Stroke Length |

mm |

350 |

350 |

350 |

350 |

400 |

||

|

Strokes per Minute |

SPM |

~50 |

~50 |

~50 |

~50 |

~50 |

||

|

Tonnage Rating Point |

mm |

6.5 |

6.5 |

6.5 |

6.5 |

6.5 |

||

|

Die Height |

mm |

700 |

700 |

700 |

800 |

800 |

||

|

Slide Adjustment |

mm |

250 |

250 |

250 |

300 |

300 |

||

|

Slide Area |

1 |

mm |

2500×2000 |

2500×2000 |

2500×2000 |

2800×2200 |

3100×2200 |

|

|

2 |

2800×2000 |

2800×2000 |

2800×2000 |

3100×2200 |

3400×2200 |

|||

|

3 |

3100×2000 |

3100×2000 |

3100×2000 |

3400×2200 |

3700×2200 |

|||

|

4 |

3400×2000 |

3400×2000 |

3400×2000 |

3700×2200 |

4000×2200 |

|||

|

Bolster

Area |

1 |

mm |

2500×2000 |

2500×2000 |

2500×2000 |

2800×2200 |

3100×2200 |

|

|

2 |

2800×2000 |

2800×2000 |

2800×2000 |

3100×2200 |

3400×2200 |

|||

|

3 |

3100×2000 |

3100×2000 |

3100×2000 |

3400×2200 |

3700×2200 |

|||

|

4 |

3400×2000 |

3400×2000 |

3400×2000 |

3700×2200 |

4000×2200 |

|||

|

Bolster Thickness |

mm |

180 |

180 |

250 |

250 |

250 |

||

|

Window Opening |

Bolster Only |

(FB × UD) |

mm |

1800×600 |

1800×600 |

1800×600 |

2000×700 |

2000×700 |

|

Front to Back Rolling Bolster |

1800×600 |

1800×600 |

1800×600 |

2000×700 |

2000×700 |

|||

|

Left to Right Rolling Bolster |

2300×800 |

2300×800 |

2300×800 |

2500×900 |

2500×900 |

|||

|

Max. Upper Die Weight |

Ton |

8 |

8 |

9 |

10 |

10 |

||

|

Required Air Pressure |

MPa |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

||

|

Bolster Height |

Fixed Bolster |

mm |

660 |

660 |

660 |

660 |

740 |

|

|

Rolling Bolster |

||||||||

|

Die Cushion |

Type |

Cylinder |

Cylinder |

Cylinder |

Cylinder |

Cylinder |

||

|

Capacity |

kN |

600 |

800 |

1000 |

1200* |

1500 |

||

|

Stroke Length |

mm |

200 |

200 |

200 |

220 |

220 |

||

|

Adjustment |

mm |

200 |

200 |

200 |

220 |

220 |

||

|

Cushion Pad Area |

1 |

mm |

2000×1300 |

2000×1300 |

2000×1300 |

2300×1500 |

2600×1500 |

|

|

2 |

2300×1300 |

2300×1300 |

2300×1300 |

2600×1500 |

2900×1500 |

|||

|

3 |

2600×1300 |

2600×1300 |

2600×1300 |

2900×1500 |

3200×1500 |

|||

|

4 |

2900×1300 |

2900×1300 |

2900×1300 |

3200×1500 |

3500×1500 |

|||

|

Model |

SDG4-1200 |

SDG4-1600 |

SDG4-2000 |

SDG4-2400 |

|||

|

Capacity |

kN |

12000 |

16000 |

20000 |

24000 |

||

|

Stroke Length |

mm |

400 |

450 |

450 |

450 |

||

|

Strokes per Minute |

SPM |

~50 |

~40 |

~40 |

~40 |

||

|

Tonnage Rating Point |

mm |

6.5 |

6.5 |

6.5 |

6.5 |

||

|

Die Height |

mm |

800 |

900 |

1000 |

1000 |

||

|

Slide Adjustment |

mm |

300 |

300 |

300 |

300 |

||

|

Slide Area |

1 |

mm |

3400×2200 |

3400×2200 |

4000×2200 |

4000×2200 |

|

|

2 |

3700×2200 |

3700×2200 |

4300×2200 |

4300×2200 |

|||

|

3 |

4000×2200 |

4000×2200 |

4600×2200 |

4600×2200 |

|||

|

4 |

4300×2200 |

4300×2200 |

4900×2200 |

4900×2200 |

|||

|

Bolster

Area |

1 |

mm |

3400×2200 |

3400×2200 |

4000×2200 |

4000×2200 |

|

|

2 |

3700×2200 |

3700×2200 |

4300×2200 |

4300×2200 |

|||

|

3 |

4000×2200 |

4000×2200 |

4600×2200 |

4600×2200 |

|||

|

4 |

4300×2200 |

4300×2200 |

4900×2200 |

4900×2200 |

|||

|

Bolster Thickness |

mm |

300 |

300 |

300 |

300 |

||

|

Window Opening |

Bolster Only |

(FB × UD) |

mm |

2000×700 |

2000×800 |

2000×900 |

2000×900 |

|

Front to Back Rolling Bolster |

2000×700 |

2000×800 |

2000×900 |

2000×900 |

|||

|

Left to Right Rolling Bolster |

2500×900 |

2500×1000 |

2500×1100 |

2500×1100 |

|||

|

Max. Upper Die Weight |

Ton |

11 |

13 |

15 |

20 |

||

|

Required Air Pressure |

MPa |

0.6 |

0.6 |

0.6 |

0.6 |

||

|

Bolster Height |

Fixed Bolster |

mm |

740 |

740 |

740 |

740 |

|

|

Rolling Bolster |

|||||||

|

Die Cushion |

Type |

Cylinder |

Cylinder |

Cylinder |

Cylinder |

||

|

Capacity |

kN |

1500 |

2000 |

2400 |

3000 |

||

|

Stroke Length |

mm |

220 |

220 |

220 |

250 |

||

|

Adjustment |

mm |

220 |

220 |

220 |

250 |

||

|

Cushion Pad Area |

1 |

mm |

2900×1500 |

2900×1500 |

3500×1500 |

3500×1500 |

|

|

2 |

3200×1500 |

3200×1500 |

3800×1500 |

3800×1500 |

|||

|

3 |

3500×1500 |

3500×1500 |

4100×1500 |

4100×1500 |

|||

|

4 |

3800×1500 |

3800×1500 |

4400×1500 |

4400×1500 |

|||

* For selecting 1200kN, 1500kN and 2000kN air cylinder die cushions, bolster area in FB should be at least 1700mm, cushion area in FB should be 1300mm.

** For SDG2-800-1, only 1000kN die cushion is available.

* For SDG4-800-1, only 1000kN die cushion is available.

※ This specification is subject to change without notice.

|

Model |

SDG2-400 |

SDG2-600 |

SDG2-800 |

SDG2-1000 |

SDG2-1200 |

|||

|

Capacity |

U.S. ton |

440 |

660 |

880 |

1100 |

1320 |

||

|

Stroke Length |

in |

13.78 |

13.78 |

13.78 |

15.75 |

15.75 |

||

|

Pendulum Motion Stroke Length |

in |

3.94 |

3.94 |

3.94 |

3.94 |

3.94 |

||

|

Strokes per Minute |

SPM |

~50 |

~50 |

~50 |

~50 |

~50 |

||

|

Pendulum Motion Strokes per Minute |

SPM |

~ 74 |

~ 74 |

~ 74 |

~ 72 |

~ 72 |

||

|

Tonnage Rating Point |

in |

0.26 |

0.26 |

0.26 |

0.26 |

0.26 |

||

|

Die Height |

in |

27.56 |

27.56 |

31.50 |

31.50 |

31.50 |

||

|

Slide Adjustment |

in |

9.84 |

9.84 |

11.81 |

11.81 |

11.81 |

||

|

Slide Area |

1 |

in |

98.43×55.12 |

98.43×61.02 |

110.24×61.02 |

122.05×61.02 |

133.86×61.02 |

|

|

2 |

110.24×55.12 |

110.24×61.02 |

122.05×61.02 |

133.86×61.02 |

145.67×61.02 |

|||

|

3 |

122.05×55.12 |

122.05×61.02 |

133.86×61.02 |

145.67×61.02 |

157.48×61.02 |

|||

|

4 |

133.86×55.12 |

133.86×61.02 |

145.67×61.02 |

157.48×61.02 |

169.29×61.02 |

|||

|

Bolster

Area |

1 |

in |

98.43×55.12 |

98.43×61.02 |

110.24×61.02 |

122.05×61.02 |

133.86×61.02 |

|

|

2 |

110.24×55.12 |

110.24×61.02 |

122.05×61.02 |

133.86×61.02 |

145.67×61.02 |

|||

|

3 |

122.05×55.12 |

122.05×61.02 |

133.86×61.02 |

145.67×61.02 |

157.48×61.02 |

|||

|

4 |

133.86×55.12 |

133.86×61.02 |

145.67×61.02 |

157.48×61.02 |

169.29×61.02 |

|||

|

Bolster Thickness |

in |

7.09 |

9.84 |

9.84 |

9.84 |

11.81 |

||

|

Window Opening |

Bolster Only |

(FB × UD) |

in |

43.31×23.62 |

51.18×23.62 |

59.06×27.56 |

59.06×27.56 |

59.06×27.56 |

|

Front to Back Rolling Bolster |

43.31×23.62 |

51.18×23.62 |

59.06×27.56 |

59.06×27.56 |

59.06×27.56 |

|||

|

Left to Right Rolling Bolster |

66.93×31.50 |

72.83×31.50 |

72.83×35.43 |

72.83×35.43 |

72.83×35.43 |

|||

|

Max. Upper Die Weight |

LBS |

8818 |

11023 |

12125 |

13228 |

15432 |

||

|

Required Air Pressure |

PSI |

71 |

71 |

71 |

71 |

71 |

||

|

Bolster Height |

Fixed Bolster |

in |

33.46 |

33.46 |

33.46 |

33.46 |

33.46 |

|

|

Rolling Bolster |

25.98 |

25.98 |

25.98 |

29.13 |

29.13 |

|||

|

Die Cushion |

Type |

Cylinder |

Cylinder |

Cylinder* |

Cylinder* |

Cylinder* |

||

|

Capacity |

U.S ton |

66 |

110 |

132** |

165 |

165 |

||

|

Stroke Length |

in |

7.87 |

7.87 |

8.66 |

8.66 |

8.66 |

||

|

Adjustment |

in |

7.87 |

7.87 |

8.66 |

8.66 |

8.66 |

||

|

Cushion Pad Area |

1 |

in |

78.74×35.43 |

78.74×37.40 |

90.55×51.18 |

102.36×51.18 |

114.17×51.18 |

|

|

2 |

90.55×35.43 |

90.55×37.40 |

102.36×51.18 |

114.17×51.18 |

125.98×51.18 |

|||

|

3 |

102.36×35.43 |

102.36×37.40 |

114.17×51.18 |

125.98×51.18 |

137.80×51.18 |

|||

|

4 |

114.17×35.43 |

114.17×37.40 |

125.98×51.18 |

137.80×51.18 |

149.61×51.18 |

|||

|

Model |

SDG4-440 |

SDG4-550 |

SDG4-660 |

SDG4-880 |

SDG4-1100 |

|||

|

Capacity |

U.S. ton |

440 |

550 |

660 |

880 |

1100 |

||

|

Stroke Length |

in |

13.78 |

13.78 |

13.78 |

13.78 |

15.75 |

||

|

Strokes per Minute |

SPM |

~50 |

~50 |

~50 |

~50 |

~50 |

||

|

Tonnage Rating Point |

in |

0.26 |

0.26 |

0.26 |

0.26 |

0.26 |

||

|

Die Height |

in |

27.56 |

27.56 |

27.56 |

31.50 |

31.50 |

||

|

Slide Adjustment |

in |

9.84 |

9.84 |

9.84 |

11.81 |

11.81 |

||

|

Slide Area |

1 |

in |

98.43×78.74 |

98.43×78.74 |

98.43×78.74 |

110.24×86.61 |

122.05×86.61 |

|

|

2 |

110.24×78.74 |

110.24×78.74 |

110.24×78.74 |

122.05×86.61 |

133.86×86.61 |

|||

|

3 |

122.05×78.74 |

122.05×78.74 |

122.05×78.74 |

133.86×86.61 |

145.67×86.61 |

|||

|

4 |

133.86×78.74 |

133.86×78.74 |

133.86×78.74 |

145.67×86.61 |

157.48×86.61 |

|||

|

Bolster

Area |

1 |

in |

98.43×78.74 |

98.43×78.74 |

98.43×78.74 |

110.24×86.61 |

122.05×86.61 |

|

|

2 |

110.24×78.74 |

110.24×78.74 |

110.24×78.74 |

122.05×86.61 |

133.86×86.61 |

|||

|

3 |

122.05×78.74 |

122.05×78.74 |

122.05×78.74 |

133.86×86.61 |

145.67×86.61 |

|||

|

4 |

133.86×78.74 |

133.86×78.74 |

133.86×78.74 |

145.67×86.61 |

157.48×86.61 |

|||

|

Bolster Thickness |

in |

7.09 |

7.09 |

9.84 |

9.84 |

9.84 |

||

|

Window Opening |

Bolster Only |

(FB × UD) |

in |

70.87×23.62 |

70.87×23.62 |

70.87×23.62 |

78.74×27.56 |

78.74×27.56 |

|

Front to Back Rolling Bolster |

70.87×23.62 |

70.87×23.62 |

70.87×23.62 |

78.74×27.56 |

78.74×27.56 |

|||

|

Left to Right Rolling Bolster |

90.55×31.50 |

90.55×31.50 |

90.55×31.50 |

98.43×35.43 |

98.43×35.43 |

|||

|

Max. Upper Die Weight |

LBS |

17636 |

17636 |

19841 |

22046 |

22046 |

||

|

Required Air Pressure |

PSI |

71 |

71 |

71 |

71 |

71 |

||

|

Bolster Height |

Fixed Bolster |

in |

25.98 |

25.98 |

25.98 |

25.98 |

29.13 |

|

|

Rolling Bolster |

||||||||

|

Die Cushion |

Type |

Cylinder |

Cylinder |

Cylinder |

Cylinder |

Cylinder |

||

|

Capacity |

U.S. ton |

66 |

88 |

110 |

132* |

165 |

||

|

Stroke Length |

in |

7.87 |

7.87 |

7.87 |

8.66 |

8.66 |

||

|

Adjustment |

in |

7.87 |

7.87 |

7.87 |

8.66 |

8.66 |

||

|

Cushion Pad Area |

1 |

in |

78.74×51.18 |

78.74×51.18 |

78.74×51.18 |

90.55×59.06 |

102.36×59.06 |

|

|

2 |

90.55×51.18 |

90.55×51.18 |

90.55×51.18 |

102.36×59.06 |

114.17×59.06 |

|||

|

3 |

102.36×51.18 |

102.36×51.18 |

102.36×51.18 |

114.17×59.06 |

125.98×59.06 |

|||

|

4 |

114.17×51.18 |

114.17×51.18 |

114.17×51.18 |

125.98×59.06 |

137.80×59.06 |

|||

|

Model |

SDG4-1320 |

SDG4-1760 |

SDG4-2200 |

SDG4-2640 |

|||

|

Capacity |

U.S. ton |

1320 |

1760 |

2200 |

2640 |

||

|

Stroke Length |

in |

15.75 |

17.72 |

17.72 |

17.72 |

||

|

Strokes per Minute |

SPM |

~50 |

~40 |

~40 |

~40 |

||

|

Tonnage Rating Point |

in |

0.26 |

0.26 |

0.26 |

0.26 |

||

|

Die Height |

in |

31.50 |

35.43 |

39.37 |

39.37 |

||

|

Slide Adjustment |

in |

11.81 |

11.81 |

11.81 |

11.81 |

||

|

Slide Area |

1 |

mm |

133.86×86.61 |

133.86×86.61 |

157.48×86.61 |

157.48×86.61 |

|

|

2 |

145.67×86.61 |

145.67×86.61 |

169.29×86.61 |

169.29×86.61 |

|||

|

3 |

157.48×86.61 |

157.48×86.61 |

181.10×86.61 |

181.10×86.61 |

|||

|

4 |

169.29×86.61 |

169.29×86.61 |

192.91×86.61 |

192.91×86.61 |

|||

|

Bolster

Area |

1 |

in |

133.86×86.61 |

133.86×86.61 |

157.48×86.61 |

157.48×86.61 |

|

|

2 |

145.67×86.61 |

145.67×86.61 |

169.29×86.61 |

169.29×86.61 |

|||

|

3 |

157.48×86.61 |

157.48×86.61 |

181.10×86.61 |

181.10×86.61 |

|||

|

4 |

169.29×86.61 |

169.29×86.61 |

192.91×86.61 |

192.91×86.61 |

|||

|

Bolster Thickness |

in |

11.81 |

11.81 |

11.81 |

11.81 |

||

|

Window Opening |

Bolster Only |

(FB × UD) |

in |

78.74×27.56 |

78.74×31.50 |

78.74×35.43 |

78.74×35.43 |

|

Front to Back Rolling Bolster |

78.74×27.56 |

78.74×31.50 |

78.74×35.43 |

78.74×35.43 |

|||

|

Left to Right Rolling Bolster |

98.43×35.43 |

98.43×39.37 |

98.43×43.31 |

98.43×43.31 |

|||

|

Max. Upper Die Weight |

LBS |

24250 |

28660 |

33069 |

44092 |

||

|

Required Air Pressure |

PSI |

71 |

71 |

71 |

71 |

||

|

Bolster Height |

Fixed Bolster |

in |

29.13 |

29.13 |

29.13 |

29.13 |

|

|

Rolling Bolster |

|||||||

|

Die Cushion |

Type |

Cylinder |

Cylinder |

Cylinder |

Cylinder |

||

|

Capacity |

U.S. ton |

165 |

220 |

262 |

330 |

||

|

Stroke Length |

in |

8.66 |

8.66 |

8.66 |

9.84 |

||

|

Adjustment |

in |

8.66 |

8.66 |

8.66 |

9.84 |

||

|

Cushion Pad Area |

1 |

in |

114.17×59.06 |

114.17×59.06 |

137.80×59.06 |

137.80×59.06 |

|

|

2 |

125.98×59.06 |

125.98×59.06 |

149.61×59.06 |

149.61×59.06 |

|||

|

3 |

137.80×59.06 |

137.80×59.06 |

161.42×59.06 |

161.42×59.06 |

|||

|

4 |

149.61×59.06 |

149.61×59.06 |

173.23×59.06 |

173.23×59.06 |

|||

* For selecting 132ton, 165ton and 220ton air cylinder die cushions, bolster area in FB should be at least 1700mm, cushion area in FB should be 1300mm.

** For SDG2-880-1, only 110ton die cushion is available.

* For SDG4-880-1, only 110ton die cushion is available.

※ This specification is subject to change without notice.