News

SEYI Shines at FABTECH and EuroBLECH 2024: A Recap of Our Latest Innovations and Industry Impact

This fall, SEYI showcased our metal stamping services at two of the world’s premier tradeshows for the sheet metal industry—FABTECH 2024 and EuroBLECH 2024. These events provided invaluable platforms to present SEYI’s latest technologies, including the debut of the SDN1 Series servo gap frame press in North America and our energy-efficient and smart factory concepts in Europe.

Spotlight on the SEYI SDN1 Series Servo Press at FABTECH

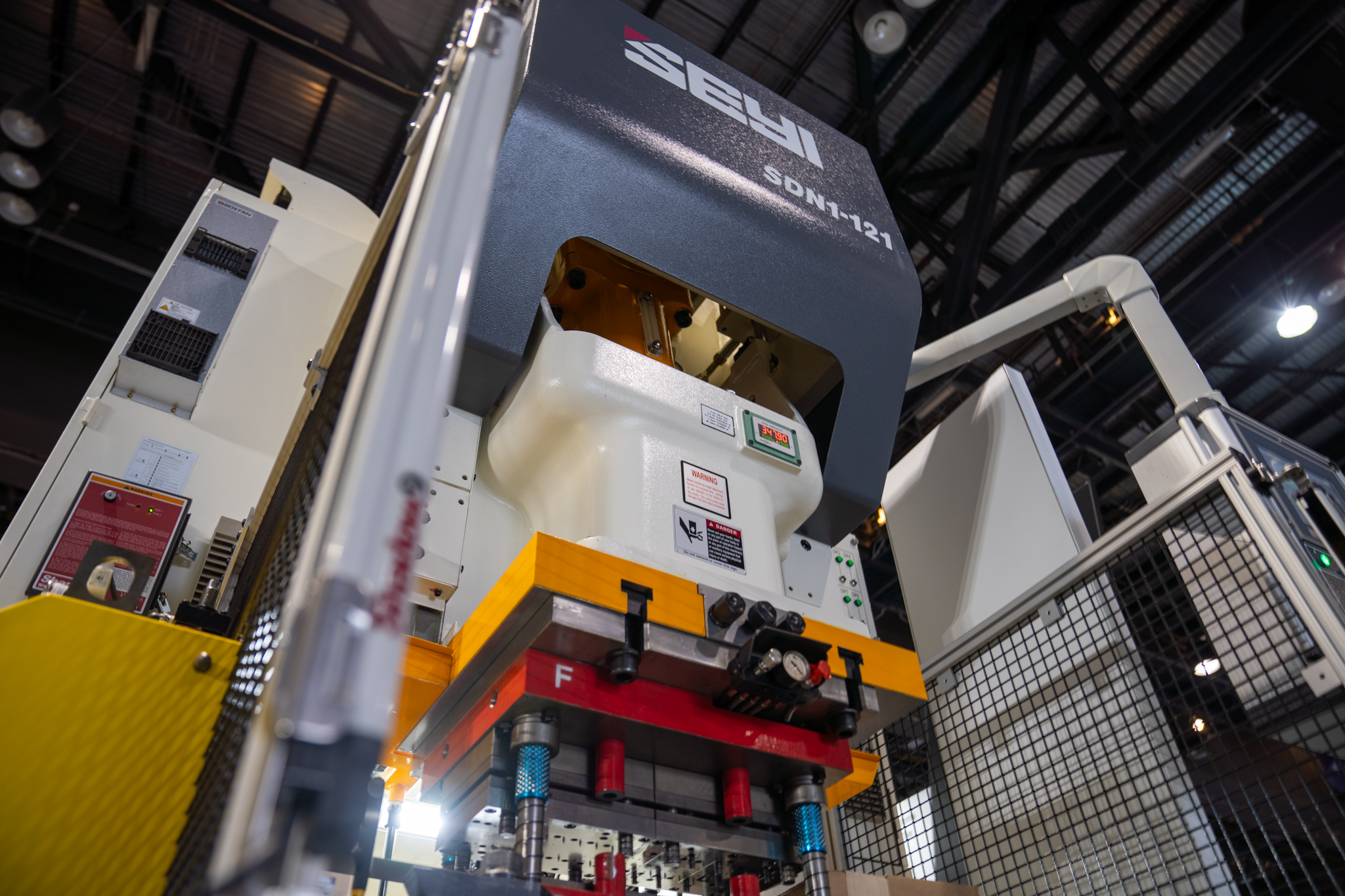

As North America’s largest event dedicated to metal forming, FABTECH 2024 welcomed industry professionals and experts to Orlando, FL for the first time. SEYI’s booth emphasized its servo technology with its debut of the SDN1 Series servo gap frame press. Visitors were able to explore how the SDN1 Series enhances manufacturing flexibility through customizable motion profiles, reducing cycle times and improving part quality to provide higher returns.

|

Specifically, the SDN1-121 at the booth housed a complex die that created a sophisticated electric vehicle. This EV part was stamped using 20 stations featuring gags and in-die assembly, layering 11 sheets of 70mm x 1.6mm thick steel. To accommodate this process, the servo press was equipped with a customized stroke profile to meet the high standards of the die. Visitors were able to interact with the servo’s Beckhoff controls to view the intricacies of the stroke.

Learn more about SEYI's Gap Frame Servo Press. |

|

Collaboration with COE Feedlines |

|

EuroBLECH 2024: Expanding SEYI’s Presence in Europe

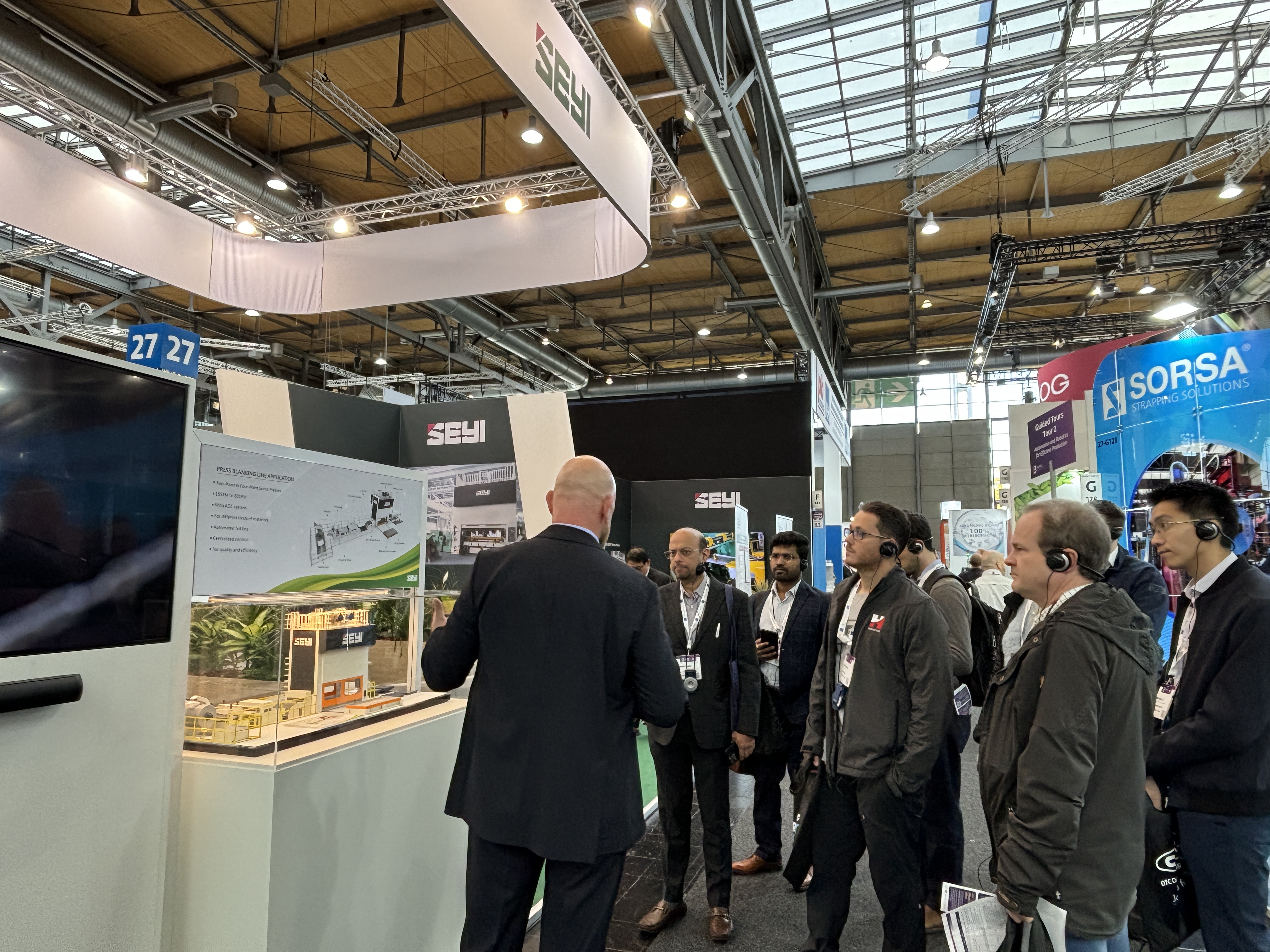

EuroBLECH 2024, held at the Deutsche Messe in Hanover, brought together 1,422 exhibitors and nearly 38,000 visitors from across Europe and beyond. At the SEYI Europe booth, we focused on energy conservation and smart factory . Our booth design reflected these values with green elements, stamping samples, interactive touch screens for virtual demos, and a virtual showroom.

Visitors enjoyed exploring demo videos of different workpieces on our touch screens, while SEYI representatives provided in-depth explanations. The booth’s design received many compliments for its style, helping SEYI strengthen its branding in the European market.

|

Engaging with Customers Through Seminars and Interactive Demos

Two daily seminars led by experts provided solutions to customer challenges, allowing potential clients to engage directly with both business and technical teams. Through this interactive setup and the presence of machinery experts, SEYI demonstrated a commitment to comprehensive customer support from product design to after-sales service.

Looking ahead, SEYI Europe will continue to strengthen our brand’s presence in Europe, with plans to attend Blechexpo 2025 in Stuttgart and expand our marketing efforts in the region.

|

Key Industry Trends and SEYI’s Role

Throughout both FABTECH and EuroBLECH, several notable trends emerged:

-

Integrated Production Solutions: Complete production lines were a key theme, highlighted by SEYI’s collaboration with COE, demonstrating efficient and synchronized stamping solutions.

-

Precision and Flexibility: Manufacturers are increasingly seeking adaptable press solutions. SEYI’s servo technology offers customizable motion profiles, allowing greater control over each step of the stamping process.

-

Smart Manufacturing and Automation: Automation remains a priority, with SEYI’s presses designed to integrate seamlessly with SIMS packages and Industry 4.0 systems to support automated stamping lines.

Looking Forward: Building Connections and Strengthening the SEYI Brand

Both FABTECH and EuroBLECH allowed SEYI to connect with industry leaders, exchange insights on emerging challenges, and showcase solutions that meet evolving manufacturing needs. We look forward to building on the connections established at these events and collaborating with partners to drive better manufacturing outcomes.

For more information on SEYI’s innovations, including the SDN1 Series servo gap frame press, visit our website or contact us to discover how we can support your production goals.