News

SEYI Successfully Demonstrated High-Rigidity, High-Precision Servo Press at MF-Tokyo 2025 with Metallic Bipolar Plate Application

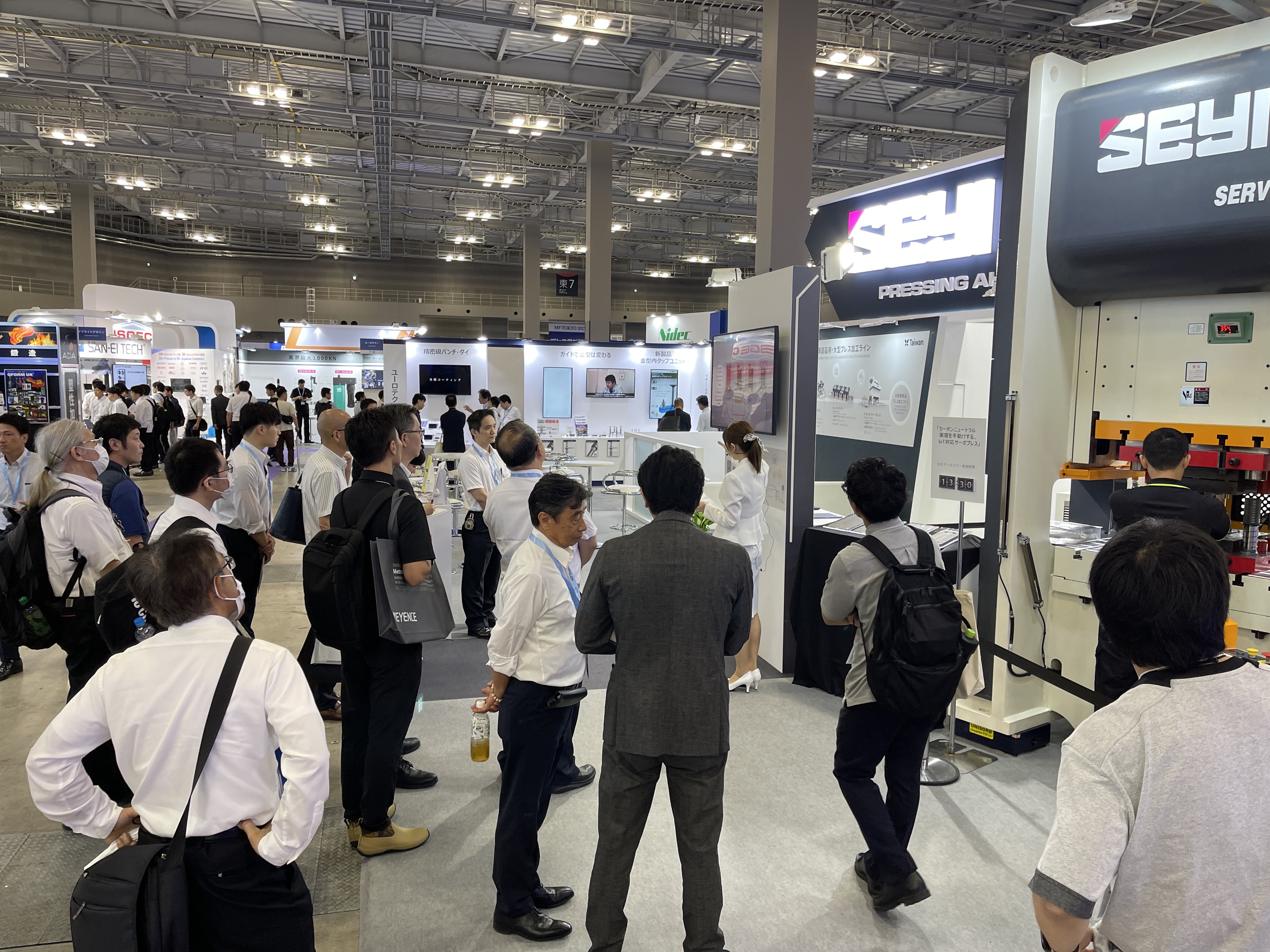

The 8th Metal Forming Fair Tokyo "MF-Tokyo 2025" ended successfully on July 19 at the Tokyo International Exhibition Center (Tokyo Big Sight), with over 31,000 visitors attending the event. SEYI exhibited a high-rigidity, high-precision solid frame servo press at its booth, demonstrating the Fuel Cell metallic bipolar plate stamping application. Additionally, we introduced new energy vehicle solutions, smart stamping solutions, integrated press line solutions for various stamping production lines, and the showcase for ESG achievements.

During the show, Dr. KC Hsu, representing SEYI, was interviewed by the event organizer. As an expert in servo stamping, he introduced servo presses and the applications showcased at the event, highlighting several key features. You can watch the introduction video here.

SEYI has participated MF-Tokyo event since the second round, and this year is its sixth participation. Many exhibitors focused on IoT applications and core component processing for electric vehicles. SEYI was one of the two exhibitors showcasing bipolar plate stamping with live demonstration and the only one showcasing large bipolar plate samples at the booth. This attracted many visitors from the automotive and home appliance industries and grabbed Japanese peers' attention significantly. Meanwhile, our actions and contributions to ESG sustainable development also impressed our customers.

SEYI exhibited a 160-ton high-rigidity, high-precision solid frame servo press, designed with a high-rigidity structure to enhance the processing stability and precision. This press performs exceptionally well in micro-scaled flow channel forming of ultra-thin plates, meeting the critical processing requirements of metallic bipolar plates for hydrogen fuel cell vehicles. Equipped with a high-torque servo motor, it effectively improves energy conversion efficiency and reduces power costs. The standard configuration includes a circulating lubrication system, with both energy-saving and environmental benefits.

The booth featured several daily demonstrations with professional explanations, proofing SEYI's servo press performance in thin plate stamping and the uniformity of the flow channel depth control. This meets the high requirements for fuel cell bipolar plate flow channel forming in new energy vehicles. The booth also displayed samples of each processing stage, providing visitors with a better understanding of the forming processes.

Various Press Line Solutions

The booth also introduced integrated press line solutions and achievements, including large press tandem lines, blanking lines, hot stamping, and transfer presses, commonly seen in the automotive industry. SEYI has numerous successful cases in Europe, China, and Southeast Asia. For more information, please click here to learn more about stamping applications.

To meet customer demands for smart stamping production, SEYI also introduced the smart stamping solution (SIMS+), developed based on IoT technology , along with customer success stories using the SIMS+ system. The system records and saves various data by deploying multiple sensors as well as monitors and records production process images with surveillance cameras. This system allows real-time monitoring of production and machine status, with data and statistics accessible via laptops, smart phones, or tablets, facilitating data extraction for further analysis and optimization of production decisions.

We thank all the visitors including our customers and industry leaders for visiting SEYI's booth at MF-TOKYO 2025, sharing insights on the topic of the efficient, smart, and low-carbon manufacturing. SEYI will continue to uphold its vision with the advanced stamping technology, professional knowledge, and sustainable growth, driving the future of metal forming.