Featured Articles

SEYI Servo Press: NN Inc.’s Gateway to EV Manufacturing

NN, Inc. is a precision component manufacturer with extensive experience in machining, stamping, and welding for a wide range of markets, including electrical switching, electrical power steering, high voltage connectors, and general industrial sectors. With locations in six countries, NN Inc, is a global enterprise that serves the world with its extensive industry experience.

As global demand increased, especially in the automotive sector, high-performance stamping became a focus. INN Inc. began looking to SEYI presses in 2017 for their reputation as excellent suppliers and services for metal stamping equipment. What initially began a single press project has now grown to 6 SEYI presses –and counting – in the United States.

Eric Hauser, Plant Manager at NN’s Massachusetts facility, shared that the benefits of working with SEYI have been substantial. “We’ve seen increased output, more flexibility in the types of parts we can run, reduced downtime, and simpler day-to-day operations,” he said. The transition to SEYI equipment has not only streamlined production but also positioned NN Inc. for new opportunities—especially in the fast-growing EV market.

NN Inc.’s Servo Integration

NN Inc. first partnered with SEYI to supply two SN2-220 gap frame mechanical presses. The reliability of the equipment and ease of service quickly earned the trust of Eric and the NN production team. “Those presses are what gave us the indication of the quality of the press – I can’t even remember any major repairs we’ve had – so that obviously laid the groundwork for who we want to consider for our servo press,” said Eric.

Given the complexity of many of NN Inc.’s EV components, efficiency both in equipment and personnel is critical to their operation. With a large portion of the workforce approaching retirement, one of NN’s biggest challenges is maintaining a pool of experienced press operators. “Setting up presses can sometimes take a MacGyver,” said Eric, emphasizing how much of the work relies on the operator’s skill and intuition—something that typically only comes with years of hands-on experience.

Given the complexity of many of NN Inc.’s EV components, efficiency both in equipment and personnel is critical to their operation. With a large portion of the workforce approaching retirement, one of NN’s biggest challenges is maintaining a pool of experienced press operators. “Setting up presses can sometimes take a MacGyver,” said Eric, emphasizing how much of the work relies on the operator’s skill and intuition—something that typically only comes with years of hands-on experience.

While mechanical presses had long been the backbone of NN’s stamping operations, the company was eager to begin EV component manufacturing. After extensive research, they identified that a servo press with a larger bed size could open the door to producing higher precision, more complex formed parts. These components often require greater forming flexibility, which servo presses are uniquely equipped to handle thanks to their programmable stroke profiles.

Following years of evaluation, NN Inc. decided to purchase a SEYI SD2-330. The advantages quickly became clear. “The challenges we faced prior to servo technology—many of them were not even realized until we began using the equipment,” Eric noted.

The impact was substantial. NN reported up to 30% higher output on the servo press, along with noticeably improved part quality. The success of the integration was so compelling that NN Inc.’s plant in Illinois has since invested in its own SEYI SD2-176, leading to greater efficiency and expanded capabilities in high-value manufacturing markets.

Doors Opened to EV Stamping

After becoming accustomed to servo technology in the facility, NN Inc. began seeing their investment pay off as they prepared for EV Component manufacturing.

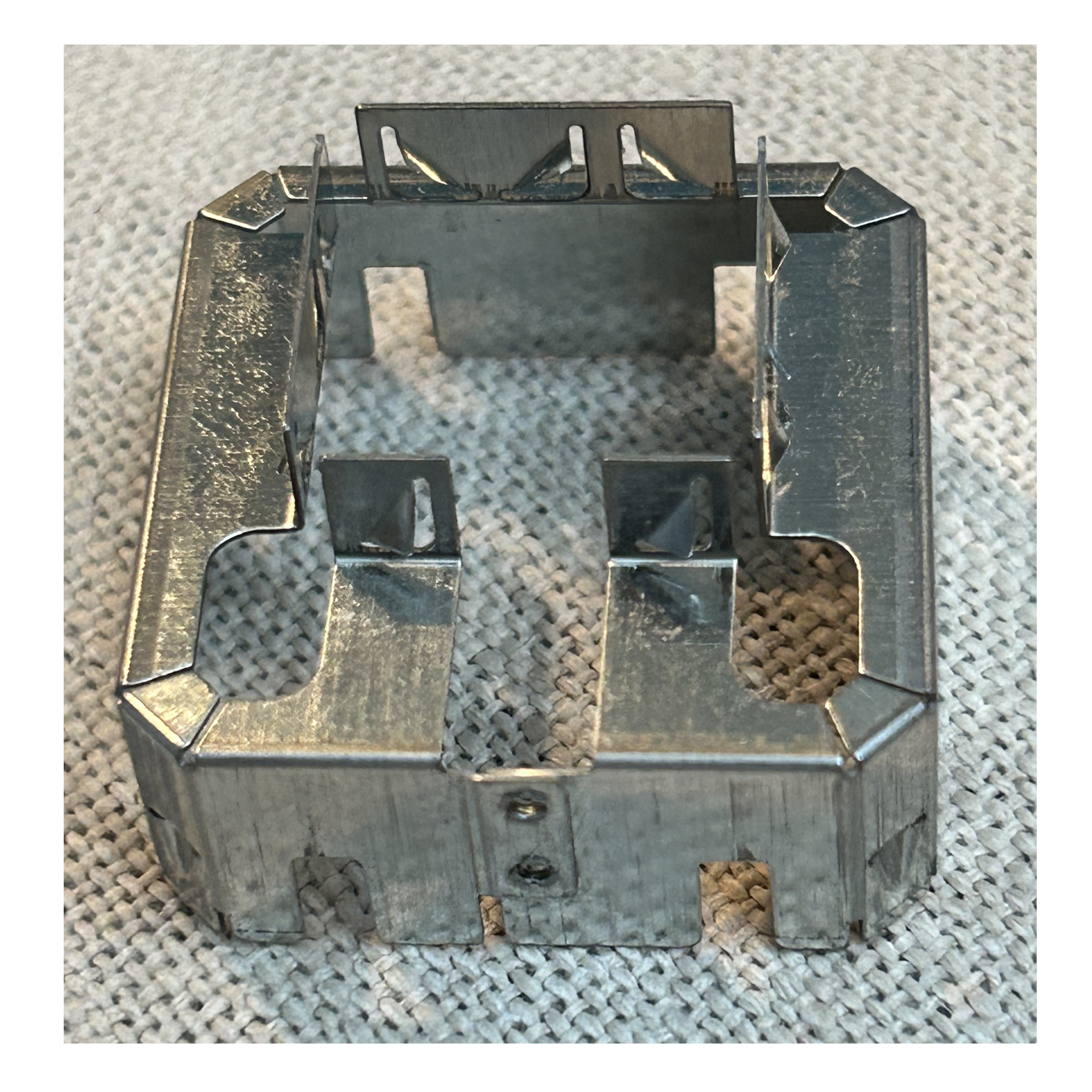

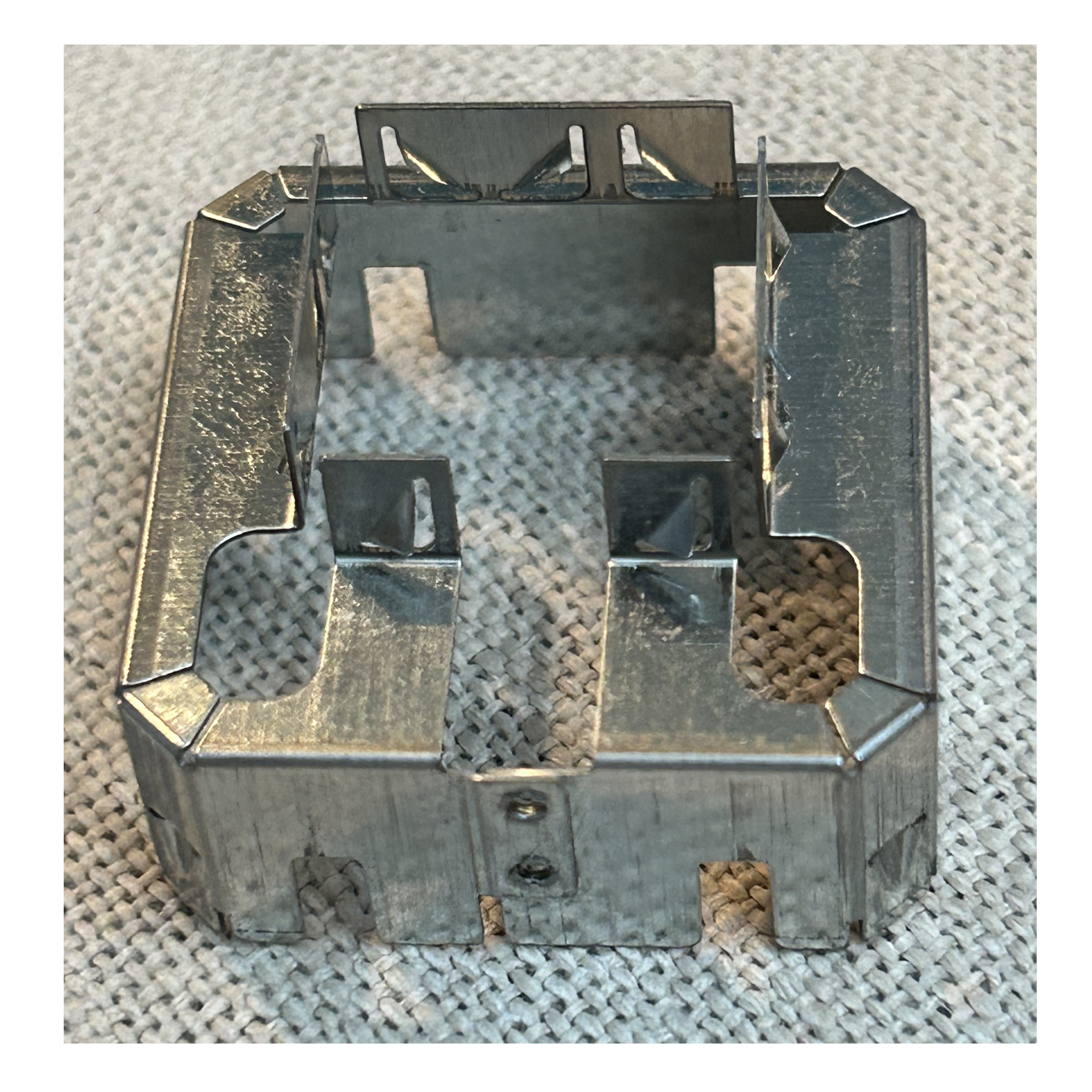

“In the EV market, there’s a lot of complex forming that really lends itself to servo technology,” said Eric. “We’re working with parts that form in multiple directions, then come together into rigid, box-type structures through staking. Some of the pieces coming out of that servo press make you stop and say, ‘This came out of a press?’” Additionally, these parts require extremely tight tolerances.

With the ability to customize the press stroke to meet precise die specifications, eliminate the need for multiple presses in a production line, and fine-tune performance for optimal part quality, the servo press has enabled NN Inc. to do what wasn’t possible with traditional mechanical presses. Today, with these advanced capabilities, NN Inc. is producing thousands of EV components for manufacturers across the U.S. through their SEYI servo press.

R&D With the Servo

With EV parts comes more sophisticated dies which brings alone its own challenges. One key feature that equips the servo press to handle this level of manufacturing is the handy pulsar wheel. This tool on the servo press allows NN Inc. and its tooling engineers to completely transform their approach to R&D and setup with their complex dies. “The handy pulsar wheel is lightyears ahead of any mechanical press,” Eric noted.

The handy pulsar wheel allows the press to do things that the mechanical simply cannot - move to any angle of the stroke while maintaining full energy. In practice, this allows the engineers at NN Inc. to precisely control the position of the slide and slowly move through the motion of the stroke in one-millimeter increments. “We can start squeezing the material a bit and then bring it back up to see how it is forming,” Eric explained.

This level of control enables NN’s toolmakers to identify and correct issues such as misfeeds, dull or uneven cutting edges, and interference during progressive forming stages. Before adopting servo technology, such issues were often difficult to detect due to the fixed motion of mechanical presses.

It further reinforces Eric’s earlier point—that many of the challenges they faced weren’t even visible until they began working with servo technology. Today, the handy pulsar wheel has become an essential tool for NN Inc.’s tooling team and stands as another reason the company confidently delivers high-quality EV components to manufacturers across the U.S.

Superior Operations for the required expertise for EV Manufacturing

Given the complexity of many of NN Inc.’s EV components, efficiency both in equipment and personnel is critical to their operation. With a large portion of the workforce approaching retirement, one of NN’s biggest challenges is maintaining a pool of experienced press operators. “Setting up presses can sometimes take a MacGyver,” said Eric, emphasizing how much of the work relies on the operator’s skill and intuition—something that typically only comes with years of hands-on experience.

Given the complexity of many of NN Inc.’s EV components, efficiency both in equipment and personnel is critical to their operation. With a large portion of the workforce approaching retirement, one of NN’s biggest challenges is maintaining a pool of experienced press operators. “Setting up presses can sometimes take a MacGyver,” said Eric, emphasizing how much of the work relies on the operator’s skill and intuition—something that typically only comes with years of hands-on experience.

“But here’s the kicker with the SEYI servo press - it’s easy to use. It’s user friendly,” stated Eric specifically about the SD2-330. He continued, “A servo is phenomenal. The mechanical presses are much more difficult to setup and operate.”

This enables NN Inc. to train newer operators on the servo press much easier. Given that all EV components are manufactured on the SEYI servo press, the level of operator experience for the EV parts is not as high given that the servo press is much simpler on a day-to-day setting.

Going Forward

NN Inc.’s investment in SEYI servo technology has proven to be more than just an equipment upgrade—it has reshaped their entire approach to stamping, tooling, and training. With improved production flexibility, higher part quality, and simplified press operation, the servo press has empowered NN Inc. to confidently enter the EV market and meet the growing demands of high-precision manufacturing. As the company continues to evolve, the partnership with SEYI remains a key driver in their ability to innovate, adapt, and lead in an increasingly complex and competitive industry.

To learn more about NN Inc. and their capabilities, click here.